Combining expertise and robust quality management to uphold the highest standards at every step—from farm to table

At Standard Foods, our Quality Management Team serves as the guardian of product safety, quality, and integrity. From sourcing raw ingredients to delivering finished products, we uphold strict standards and continuously enhance our systems to deliver safe, high-quality products consumers can rely on.

We strive to set the industry benchmark in food safety—delivering premium quality, earning unwavering brand trust, and maintaining a world-class quality management system every step of the way.

Testing Process

Every step matters when it comes to your health

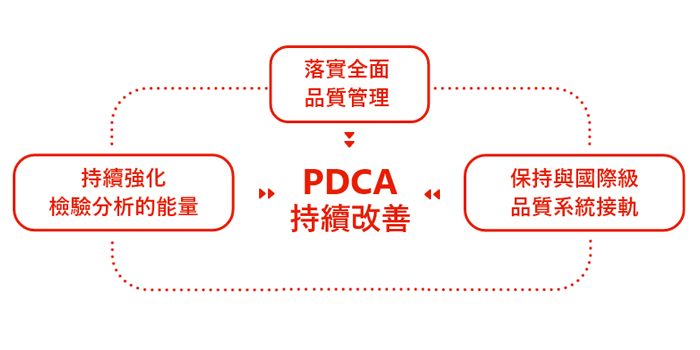

We believe every bite should be both nourishing and trusted. That's why our Quality Management Center follows the PDCA model—continuously monitoring quality at every stage and enhancing our testing and analytical capabilities. This ensures that every product we deliver meets the highest safety and quality standards.

In response to growing food safety challenges, we've established a comprehensive risk monitoring system as part of our responsibility to society. To become your most trusted choice, we strictly adhere to global standards such as ISO 22000, ensuring that every step of our production process meets internationally recognized benchmarks. We also invest in ongoing training for our teams—so every link in the chain, from sourcing raw ingredients to delivering the final product, upholds the highest standards of safety and quality, delivering a truly reliable farm-to-table experience.

We understand that every purchasing decision reflects the trust consumers place in us. Through rigorous inspection protocols and an unwavering commitment to quality, we aim to deliver more than just great taste and nutrition—we work to earn your trust with every single bite.

Internationally Certified Laboratory

Demonstrating our commitment to safety through globally recognized standards

In today's climate of heightened food safety awareness, protecting your family's health is our top priority. To strengthen inspection capabilities and elevate our quality assurance efforts, Standard Foods has made significant investments in building a state-of-the-art testing laboratory—equipped with advanced analytical instruments, including:

LC/MS/MS – Liquid Chromatography Tandem Mass Spectrometry

GC/MS/MS – Gas Chromatography Tandem Mass Spectrometry

ICP-MS – Inductively Coupled Plasma Mass Spectrometry

As our company has grown, so has our Quality Assurance team—centralizing resources and applying rigorous checks at every stage of production, from raw materials to finished products.

To uphold world-class standards and continuously refine laboratory operations, Standard Foods adheres to ISO/IEC 17025 and CNS 17025 international testing protocols. On January 16, 2025, our laboratory earned official accreditation from TAF—a milestone that reflects our ongoing commitment to food safety and global best practices.

Robust Testing Capabilities

686 in-house tests to safeguard your health

Every product we offer carries your expectations for safety and wellbeing. That's why we go beyond promises—demonstrating our commitment to quality through action.

At our Quality Management Center, we continuously enhance our inspection and analytical capabilities. We operate in full compliance with Good Manufacturing Practices (GMP), Good Hygiene Practices (GHP), and ISO 22000, the international standard for food safety management. We've also established a comprehensive Food Safety Manual and HACCP procedure, ensuring a multi-layered quality management system is firmly in place.

Currently, we conduct up to 686 in-house tests covering a wide range of critical safety checkpoints, including pesticide residues, heavy metals, mycotoxins, plasticizers, and microbial contaminants. From raw ingredients to semi-finished goods and final products, we implement rigorous, layered controls—delivering not only nutrition, but also the peace of mind that comes with safe, high-quality products you can trust.